In today’s fast-evolving electronics industry, selecting the right PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly) manufacturer is a critical decision for businesses and engineers alike. Whether you are developing consumer electronics, telecommunications equipment, medical devices, or robotics systems, the quality, reliability, and technical expertise of your PCB supplier directly influence your product’s performance, safety, and time-to-market.

This comprehensive guide explores the factors to consider when choosing a PCB and PCBA manufacturer, the advanced technologies they offer, and the industries that benefit from professional PCB fabrication services. For businesses seeking trusted partners, resources like PCBA manufacturer provide high-quality solutions for both standard and advanced printed circuit board assembly needs.

What Is a PCB and PCBA?

Understanding the difference between PCB and PCBA is essential for selecting the right manufacturer:

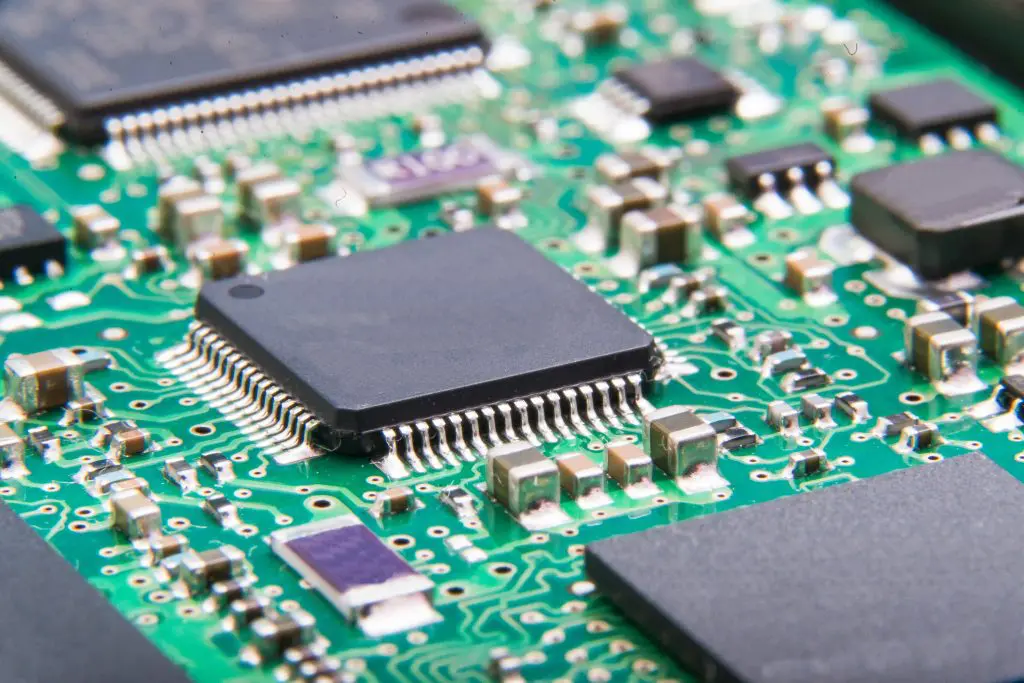

- PCB (Printed Circuit Board): A flat board used to mechanically support and electrically connect electronic components using conductive tracks, pads, and other features etched from copper sheets laminated onto a non-conductive substrate.

- PCBA (Printed Circuit Board Assembly): A PCB that has been populated with electronic components, including resistors, capacitors, microchips, connectors, and more, and is ready for integration into a final product.

A manufacturer specializing in PCBA not only fabricates the board but also assembles it to meet precise electrical, mechanical, and functional requirements.

Why Choosing the Right Manufacturer Matters

The quality of your PCB and PCBA can impact several critical aspects of your product:

- Reliability: Poor-quality boards may fail during production or operation, leading to costly recalls or repairs.

- Performance: High-frequency or advanced circuits require precise fabrication to function as intended.

- Compliance: Industry regulations often require specific certifications, such as ISO, RoHS, or IPC standards.

- Speed-to-Market: Experienced manufacturers reduce delays through efficient production, testing, and logistics.

- Cost Efficiency: A reliable manufacturer balances high quality with competitive pricing, minimizing waste and production errors.

Key Factors to Consider When Choosing a PCB Manufacturer

Selecting the right manufacturer involves evaluating several key criteria:

1. Technical Expertise

Advanced PCB design and fabrication require deep knowledge in areas such as:

- Rigid-Flex PCBs

- High-frequency PCBs

- Multilayer boards

- HDI (High-Density Interconnect) technology

- Fine-pitch component placement

Manufacturers with specialized expertise can deliver high-performance boards that meet complex requirements for telecom, robotics, aerospace, and medical industries.

2. Production Capabilities

Consider the manufacturer’s capabilities, including:

- Maximum board size

- Minimum trace width and spacing

- Layer count

- Material types

- Surface finishes (ENIG, HASL, OSP)

A supplier with advanced production equipment ensures precision, repeatability, and high-quality results.

3. Quality Standards and Certifications

Top manufacturers follow stringent quality assurance protocols, including:

- ISO 9001 quality management

- ISO 14001 environmental standards

- IPC-A-610/IPC-7711/IPC-6012 standards

- RoHS compliance

These certifications indicate a manufacturer’s commitment to consistent, reliable, and environmentally responsible production.

4. Design Support

Many manufacturers provide design for manufacturability (DFM) reviews to optimize your board layout, reduce errors, and minimize costs.

5. Testing and Inspection

Comprehensive testing is essential to ensure boards function correctly:

- AOI (Automated Optical Inspection)

- X-ray inspection for BGA and hidden solder joints

- Electrical testing (ICT, functional test)

- Thermal and environmental stress testing

6. Lead Time and Delivery

Reliable manufacturers offer fast turnaround times without compromising quality. Some provide rapid prototyping services for initial testing and validation before full-scale production.

7. Customer Support

Strong technical support and responsive communication make it easier to handle design changes, urgent orders, and troubleshooting during production.

Advanced PCB Solutions

Modern electronics often require specialized PCBs. Here are some advanced solutions manufacturers may offer:

1. Rigid-Flex PCBs

Rigid-Flex PCBs combine rigid and flexible substrates to provide:

- Space-saving design

- Reduced interconnects

- Enhanced durability

- Lightweight construction

Applications include wearable devices, aerospace systems, and compact robotics where space and weight are critical.

2. High-Frequency PCBs

High-frequency boards operate at GHz frequencies and require:

- Low-loss materials (e.g., PTFE, Rogers)

- Precise impedance control

- Minimal signal interference

Used in telecommunications, 5G devices, and radar systems, high-frequency PCBs ensure reliable signal transmission in demanding applications.

3. Multilayer PCBs

Multilayer boards allow for:

- Complex circuit designs

- Increased density of components

- Reduced board size

They are commonly used in advanced industrial electronics, servers, medical devices, and high-performance computing.

4. HDI PCBs

High-Density Interconnect (HDI) boards support fine lines, microvias, and blind/buried vias. Ideal for compact devices such as smartphones, tablets, and wearable technology.

Applications of Advanced PCBs in Industries

The versatility of modern PCBs enables innovation across multiple sectors:

1. Telecommunications

- High-speed signal transmission

- 5G and network infrastructure

- Wireless communication devices

High-frequency and multilayer PCBs are crucial for delivering performance and reliability in telecom applications.

2. Robotics

- Compact and lightweight PCBs for embedded systems

- Rigid-Flex designs for articulated joints and movable parts

- Sensor integration and automation controls

Robotics demands precision and durability, which specialized PCB manufacturers can provide.

3. Medical Devices

- Diagnostic machines

- Wearable monitors

- Imaging systems

Advanced PCBs ensure accuracy, reliability, and compliance with regulatory standards.

4. Consumer Electronics

- Smartphones, tablets, and laptops

- Smart home devices

- Audio and video equipment

HDI and multilayer PCBs allow compact designs while maintaining high performance.

5. Automotive and Aerospace

- Electric vehicles (EVs) and hybrid cars

- Navigation and control systems

- Avionics and defense applications

Durable PCBs withstand extreme temperatures, vibration, and environmental stress.

Why Partnering With a Trusted PCBA Manufacturer Matters

Working with a reputable manufacturer ensures:

- High-Quality Production: Consistent quality reduces errors and product failures.

- Faster Development Cycles: Experienced suppliers provide prototyping, testing, and design support.

- Reduced Costs: Optimized processes and material selection save money over time.

- Innovation: Access to the latest technologies like Rigid-Flex, HDI, and high-frequency solutions.

- Regulatory Compliance: Ensures products meet industry standards, essential for medical, aerospace, and telecom markets.

A trusted provider such as Global Well PCBA offers advanced PCB fabrication and assembly solutions suitable for both high-volume production and specialized prototypes.

Tips for Selecting the Right Manufacturer

- Evaluate Technical Expertise: Look for experience with your specific type of PCB or PCBA.

- Check Certifications: ISO, IPC, RoHS, and UL compliance indicate high standards.

- Review Case Studies: Examine previous projects in your industry to gauge capability.

- Ask About Testing and Quality Control: Ensure thorough inspection and functional testing.

- Consider Lead Times: Fast production and prototyping help reduce time-to-market.

- Request a DFM Review: Manufacturers with design support help optimize cost and reliability.

- Compare Pricing and Services: Balance quality with cost-effectiveness.

The Future of PCB and PCBA Manufacturing

As electronics become more sophisticated, manufacturers are adopting:

- Automated assembly lines and robotics

- AI-assisted testing and inspection

- Smart material selection for high-frequency and flexible circuits

- Environmentally friendly and RoHS-compliant materials

- Rapid prototyping with shorter iteration cycles

Keeping pace with technological advances ensures that products are competitive and reliable in global markets.

Final Thoughts

Selecting the right PCB and PCBA manufacturer is critical for ensuring product reliability, performance, and compliance. Advanced technologies such as Rigid-Flex, High-Frequency, and HDI PCBs enable innovation in industries ranging from telecommunications to robotics and medical devices.

Partnering with an experienced provider like PCBA manufacturer ensures high-quality fabrication, precise assembly, and professional support throughout the development process. By considering technical expertise, certifications, production capabilities, and design support, companies can confidently bring advanced electronics products to market with minimal risk.