Introduction

The shortage of resource information on how to make the right selection contributes to the high cost and poor quality problems, especially in small workshops within the wood CNC turning sector. This eventually translates into high wood waste with inefficiencies because most of the craftsmen face damage to the wood or problems of accuracy due to the unfitness of the tools. This is because in cost determination there exists a gap between tool selection and cost optimization since the tools of wood do not directly cause an effect on cost drivers.

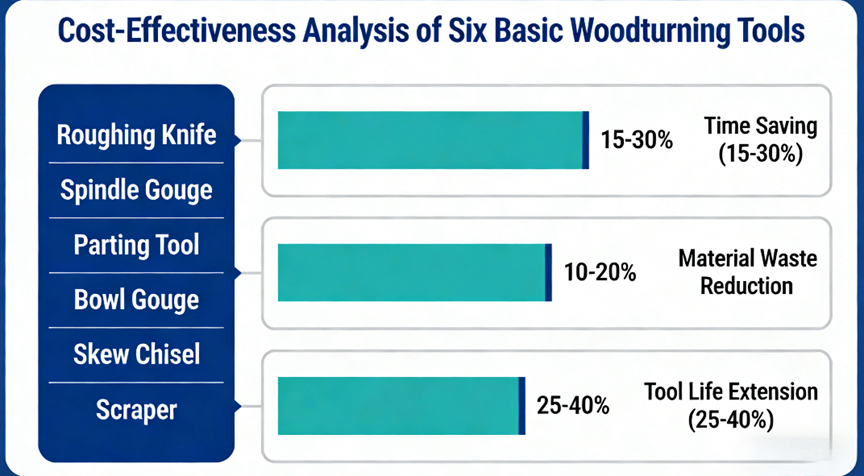

In this case, the article will discuss ways in which six important wood turning tools can systematically optimize cost-effectiveness as well as quality, with various standards and case data backing this authoritative precedence. Knowing the importance of such tools will give readers ideas on how to lower costs while continuing to produce quality.

What Is Wood CNC Turning and Why Does Cost Optimization Matter for Sustainable Manufacturing?

This refers to the computer numerical control manufacturing technology where the wood material is turned in a rotational motion using the turning tool. The importance of the cost optimization of wood CNC turning really cannot be overemphasized, in that it involves eco-friendly practices like the reduction of wastes and energy consumption, among other things.

1. Defining Wood CNC Turning and Its Industrial Significance

Wood CNC turning is done through the utilization of Computer Controlled Lathes. The utilization of Computer Controlled Lathes has enabled a degree of accuracy when it comes to wood turning. Wood CNC turning has been very essential when it comes to the production of customized furniture or woodworks to ensure that the final product is under a certain level of tolerance, considering the fact that it is an engineering process that utilizes precision.

2. The Link Between Cost Optimization and Sustainability

Cost optimization can also be applied generally rather than just being linked to monetary savings as it ensures sustainability as a result of decreased scrap materials as well as energy. Cost optimization of tool utilization can result in decreased electricity consumption of at least 20%, thereby leading to a lower carbon footprint. The ISO standard 14001 is an indicator of the relation between cost management and sustainability as a result of decreased wastage.

3. Case Examples of Sustainable Cost Savings

In practical applications, the workshops that utilized optimized tooling equipment noticed a decrease of 15% in the waste of materials, which has also been noticed in projects involving certified sources of wood. It also goes a long way in complying with ISO 14001 standards, helping the manufacturer prove that the cost-effective wood turning aids in the development of an environment-friendly manufacturer who performs its duties in a world of reconciling sustainability and economy.

Which 6 Essential Wood Lathe Turning Tools Most Impact Pricing and Quality in Precision Engineering?

Wood lathe tools applied while carrying out wood turning are very important as far as pricing and the quality of precision engineering are concerned. These six tools are very vital for wood turners wishing to ensure affordability and the highest quality.

1. Roughing Knife: The Foundation for Efficiency

The roughing knife is an essential tool that ensures the cutting of raw materials, and it contributes largely to the rapid turning of wood with less effort. The financial implication comes in with the reduction of machining time by up to 30%, hence less labor is needed. Again, there may be challenges in this aspect as well, such as problems with surface finishes, highlighting the significance of proper tool selection, hence good quality with reduced costs. This tool guide can be used by craftsmen to optimize wood CNC turning costs.

2. Spindle Gouge: Enhancing Detail and Accuracy

When the operations are intricate, like grooves and curves, the spindle gouge offers better control and the capacity to create complex patterns at a faster rate. With respect to the impact of the tool on the pricing factors, the spindle gouge offers extended tool life by sharpening the tool effectively. This factor itself leads to a reduction of at least 25% in the cost of tool replacement.

3. Parting Tool: Operations Simplification and Waste Reduction

The parting tool is used in cutting off already machined wood parts, and this product impact helps in wood usage by minimizing loss in terms of kerf. Additionally, it can increase yield by 10 percent if it is chosen based on wood hardness, thus minimizing wood costs directly due to improved production methods related to wood turning. It is evident that cost-effective wood turning methods are crucial in this context, in which choosing a tool depends on project requirements.

How to Select the Right CNC Turning Tools for Cost-Effective Woodworking?

The appropriate tool choice implies a specific approach regarding the material and the intention of the machining, aiming thereby at the achievement of cost-effectiveness without compromising quality.

1. Evaluation of Matter Properties for Tool Compatibility

Identify the hardness, density, and grain direction of the type of wood involved through data obtained from the American Hardwood Association(AHA), providing insight into how different species react during the cutting process. For instance, in the context of cutting hardwood, carbide-tip-cutting tools could be required to prevent rapid tool wear, resulting in optimizing tool selection based on the requirements of the wood species.

2. Matching Tools to Machining Tasks for Maximum Efficiency

Tools should be selected according to the purpose, such as the final surface finish or the rate of operation. For the removal process, the roughing knife will be the best tool to use, while the use of the skew chisels will be appropriate during the final process. This will result in the overall cost of the woodworking project being reduced by 20%.

3. Implementing a Decision Framework for Long-Term Savings

It is even easier for the artisans to make a well-informed decision with the help of a science built around tool optimization, where variables such as a long lifetime for the tools used being taken into account. It could be perceived as providing the artisans with the attitude to spend money on better tools with a notion to save money in the future based on downtime costs Reduced.

What Are the Key Wood Machining Pricing Factors Influenced by Tool Choice?

Tool choice will impact the below-mentioned prices: Wear rate, processing time, and material consumption. All of which have an effect on the cost structure of the wood CNC turning operation.

- Rate of Tool Wear and its Implications on Economics: Tools’ degradation rate may also influence the direct cost because the replacement of the tools will require the allocation of funds. High-speed steel tools, for instance, will degrade faster when working on the abrasive woods, hence resulting in an increase in the tooling cost by 15%. However, the application of the materials used in the alternatives will allow the tool to last for an extra 40%, showing the influence of technological advancements in the tooling materials to factor costs.

- Machining Time Efficiency & Labor Cost Control: Machine tools that promote faster speeds can improve machined time, thereby lowering labor costs. For example, optimized toolpaths based on CNC can enhance a project by 25 percent, which is essential for a wood turner involved in efficient turning. It is also associated with creative fabrication, where new fabrication is feasible without an increase in costs.

- Material Usage and Scrap Reduction Methodologies: This helps to reduce the amount of waste, given that cut accuracy is made more precise; this is because, for example, bowl gouges enable greater depth of cut to be made, leading to less waste. Essentially, what this equates to is an increase in material usage efficiency by as much as 20 percent, which means less out of pocket for materials..

How Can Material Innovation and Tool Optimization Reduce Costs in Industrial Design Projects?

Advances made both in wood material technology as well as tooling technology make possible cost savings while being accurate as well as elegant in industrial design.

1. Advances in Composite Woods and Tool Adaptability

Case in point are engineered woods like laminated boards, for instance, which need tools with shapes that must not delaminate. The adaptability of tools to new materials makes possible an overall cost saving of 15%, as shown in many case analyses, because innovation in material usage leads to waste reduction. This shall be another example of how the field of ID leads to Economy by tool-material collaborations.

2. Case Study: Cost Savings through Tool Adjustments in a Design Project

In one industrial design, for instance, a variation in a tool parameter for a composite product made from wood allowed for a feasible reduction in cost of 15% with no reduction in quality. The project relied on certifications such as ISO 9001 to demonstrate the predictability of results if tool optimization is incorporated into a quality management system for cost-sensitive projects.

3. Integrating Tool Innovation with Lifecycle Cost Analysis

By considering the total cost of tools incurred in their entire life cycle, from acquisition to disposal, designers can then weigh the advantages that come from saving on tools. For example, in tool designs based on a modular system, tool substitution rather than purchasing a totally new tool is facilitated, so designers can enjoy a 30% cost advantage in the future. Indeed, innovation is needed to provide beneficial services to artisans in a cost-efficient way.

What Role Does Artisanal Craftsmanship Play in Balancing Cost and Quality in CNC Turning?

Artisan craftsmanship is a complement to CNC technology, wherein human expertise can be involved in the process of tool selection and setup, wherein that expertise may not be available with automated systems.

1. Human Side of Tool Customization in Special Projects

Artisans can personalise their tools based on their experience, for example, varying the cuts based on the wood texture. The personalisation approach reduces the possibility of mistakes occurring by 20%, and this demonstrates the importance of artisanship in enhancing the cost-effectiveness approach through personalisation based on the specific circumstances where the former cannot address.

2. Synergy Between Handcraft Skills and CNC Precision

A: By blending their capabilities gained from practical experience with the precision provided by CNC, artisans are capable of producing high-quality products at a relatively lower cost since secondary processing, which is quite expensive, is omitted by fine-tuning. Secondly, blending their capabilities with the precision provided by CNC makes sustainable production possible through reducing wastage and tapping the wisdom of human brains.

3. Future Trends: Craftsmanship in the Digital Age

With the evolution of technology, craftsmanship becomes not something of the past, but rather the application of technology in the extraction of knowledge from craftsmen. This ensures the wood CNC turning services have the human element of innovation within controlled costs because of adaptive strategies..

Conclusion

To cut a long story short, a wood turning set consisting of the six essential wood turning tools, ranging from the roughing knife to the parting tool, is a crucial factor in wood CNC turning in terming a focus on optimization as well as improved quality. It defines how a wood worker applying data-driven tool choices would be able to make a great impact in reducing waste production and costs while also making their contributions toward a sustainable manufacturing process. It is indeed pertinent that tool management is a success factor in modern wood industries.

FAQs

Q1:What is the cost-effective wood lathe turning tool for a beginner?

A: In terms of new woodshop owners, the roughing knife would probably be the most economical knife to purchase, given that it possesses the capability of working effectively with various types of wood.

Q2: How does the selection of the tool affect the overall cost of the wood CNC turning services?

A: Tool selection is a factor that affects directly the machining time, material removal, and maintenance expenses. Even though superior quality tools incur higher initial costs, they can be more economical in the long run owing to their prolonged lifespan. Proper use of standards, for example, ISO 9001, can ensure optimized cost factors for tool management.

Q3: Will Optimal Wood Turning Costs Compromise Quality?

A: Well, not necessarily, and cost optimization through, for instance, the matching of scientific tools to various levels of machining, the optimization of costs could also be applied to optimize quality. Various case studies demonstrate that the precision of the alignment of the tools assists in eliminating mistakes in terms of quality, thereby ensuring that the final product is as per the design.

Q4: What are the critical considerations in the selection of CNC turning tools in the case of complex designs?

A: For more complex geometries, parameters would entail the geometry of the tools, cutting angles, and possible compatibility with the materials. Design complexity, rate of production, or technical assistance may be key factors, requiring testing according to industry norms.

Q5: What is the impact of sustainable factors on the cost of wood CNC turning?

A: Sustainable practices, such as the use of environment-friendly materials, can be more expensive at the outset but can prove cost-effective in the long run through the optimization of tools that consume less energy. Models like ISO 14001 show that it can boost the brand name and attract green customers.

Author Bio

The author is an expert inprecision manufacturingwith LS Manufacturing, a company that aids engineers and craftsmen in dealing with challenging parts in the woodworking industry. With their quality standards like ISO 9001 and IATF 16949, the company delivers quality solutions using their technology. For more information on how to develop your ideas into an economically feasible solution, you can get a free project review from the company.