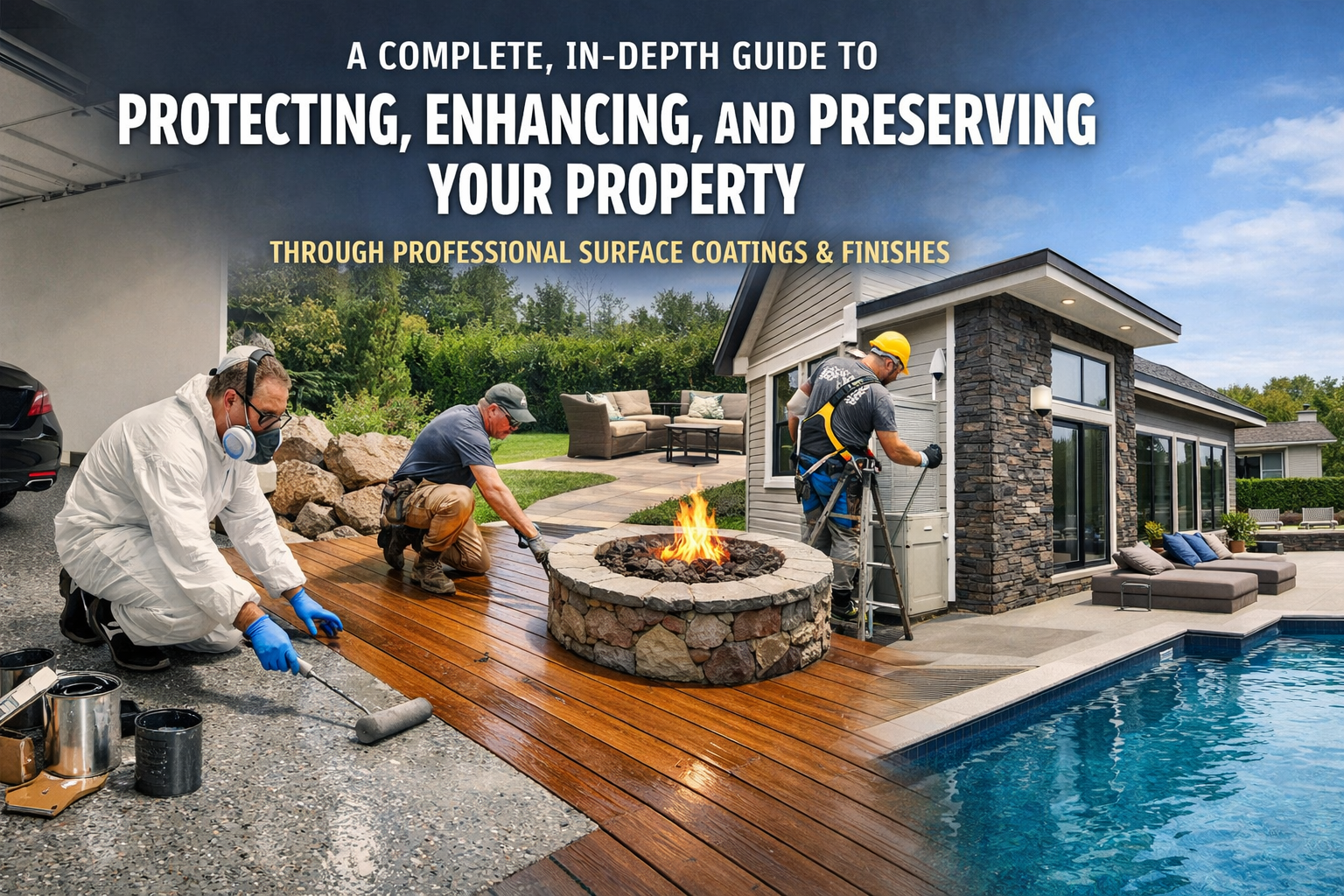

When people think about improving a property, their minds often jump straight to interior upgrades, new flooring, or modern fixtures. Yet the outside of a building is the first thing anyone sees, and it quietly absorbs the most punishment from nature every single day. Sun, rain, wind, dust, moisture, and temperature swings all leave their mark over time. A carefully planned and well-executed exterior paint project does far more than refresh appearance; it plays a critical role in protection, durability, and long-term value.

This guide explores the subject in depth, covering preparation, materials, techniques, maintenance, and the long-term advantages of doing the job correctly. Whether you are a property owner planning a project or someone wanting to understand the process at a deeper level, this article is designed to give you a complete picture without cutting corners or relying on oversimplified advice.

Why Surface Coatings on the Outside Truly Matter

The outer shell of any structure functions like a protective skin. When that layer is weak, cracked, or poorly maintained, the materials underneath are exposed to damage. Moisture can seep into wood, masonry can erode, and metal elements can corrode. Over time, these issues move beyond appearance and become structural concerns that are expensive to repair.

A high-quality exterior painting process helps seal surfaces against moisture intrusion, slows down natural wear, and shields building materials from ultraviolet damage. In climates with heavy sun exposure, proper coatings reduce fading and surface breakdown. In wetter environments, they help prevent mold, mildew, and rot. In all cases, the right application extends the life of siding, trim, and architectural details.

Beyond protection, a refreshed exterior also boosts curb appeal. A well-maintained façade signals care, quality, and pride of ownership, which can significantly influence property value and perception.

Understanding Surface Types and Their Unique Needs

Not all exteriors are created equal. Different materials require different preparation methods, primers, and finishing products. Ignoring these differences is one of the most common reasons projects fail prematurely.

Wood surfaces, for example, expand and contract with changes in humidity and temperature. They require flexible coatings that can move without cracking. Proper sanding, sealing of knots, and moisture control are essential before any finish is applied.

Masonry surfaces such as brick, stucco, or concrete are porous by nature. They need breathable coatings that allow moisture vapor to escape while still preventing water from penetrating from the outside. Applying the wrong product can trap moisture inside the wall, leading to blistering and peeling.

Metal elements, including railings or decorative features, demand thorough rust removal and specialized primers to prevent corrosion from returning. Vinyl or composite siding has its own limitations, often requiring specific formulations to ensure proper adhesion and long-lasting color stability.

Understanding the substrate is the foundation of a successful project, and it is one of the reasons experienced professionals spend so much time evaluating surfaces before any work begins.

The Critical Role of Preparation

Preparation is often underestimated because it is less visible than the final coat. However, it is the single most important stage of the entire process. Skipping or rushing prep work almost guarantees premature failure, no matter how high the quality of the paint itself.

Thorough cleaning removes dirt, chalking, mildew, and environmental residues that interfere with adhesion. Scraping and sanding eliminate loose or flaking material, creating a stable surface. Repairs address cracks, gaps, and damaged sections that could otherwise allow moisture to penetrate behind the coating.

Priming is not optional; it is a bridge between the surface and the finish. A properly chosen primer improves adhesion, enhances durability, and ensures uniform color. Each surface type benefits from a specific primer designed to meet its unique challenges.

When preparation is done correctly, the final result not only looks better but also performs better over time, resisting peeling, fading, and cracking far longer than a rushed job.

Choosing the Right Products for Long-Term Performance

Modern coating technology has advanced significantly, offering options that balance durability, environmental responsibility, and aesthetic flexibility. Water-based formulations are now widely used because they offer excellent performance, lower odor, and easier cleanup. Oil-based products still have a place in certain applications, particularly where maximum penetration or rust prevention is required.

Sheen level is another important consideration. Flat finishes can hide surface imperfections but may be less washable. Satin and semi-gloss finishes are easier to clean and often used on trim and high-traffic areas. The right balance depends on both functional needs and design preferences.

Color choice also plays a practical role. Lighter colors tend to reflect heat, which can reduce surface stress in sunny conditions. Darker colors absorb more heat and may fade faster, especially on materials sensitive to temperature changes. Understanding how color interacts with the environment helps avoid issues years down the line.

Application Techniques That Make a Difference

Even the best products can fail if applied incorrectly. Professional application techniques are designed to ensure even coverage, proper thickness, and strong adhesion.

Brushes allow precise control on detailed areas and trim. Rollers provide efficient coverage on broad, flat surfaces. Sprayers can deliver a smooth, uniform finish on large areas but require careful masking and experience to avoid overspray and uneven buildup.

Weather conditions also matter more than many people realize. Temperature, humidity, and wind all affect drying and curing. Applying coatings outside recommended conditions can lead to poor adhesion, flashing, or extended drying times that attract dust and debris.

Patience during application is essential. Allowing proper drying time between coats ensures the finish cures as intended, forming a durable protective layer rather than a fragile surface film.

Maintenance and Longevity

A well-executed exterior painting project is not a one-time event but part of an ongoing maintenance strategy. Regular inspections help catch small issues before they turn into major problems. Touching up vulnerable areas, cleaning surfaces periodically, and addressing minor damage promptly can add years to the life of the coating.

Environmental factors such as sun exposure, pollution, and nearby vegetation influence how often maintenance is needed. Shaded areas may be more prone to mildew, while sun-exposed walls may experience faster fading. Understanding these patterns allows property owners to plan proactive care instead of reacting to visible deterioration.

Over time, even the best finishes will reach the end of their service life. When that happens, the presence of good preparation and quality materials from previous projects makes repainting easier, faster, and more cost-effective.

Value Beyond Appearance

While visual improvement is often the most obvious benefit, the true value lies beneath the surface. A properly protected exterior helps prevent costly repairs related to moisture damage, rot, and material failure. It also contributes to energy efficiency by sealing gaps and reducing heat absorption in certain conditions.

For property owners considering resale, a well-maintained exterior can significantly influence buyer perception. It creates a positive first impression and signals that the property has been cared for, which can translate into higher offers and faster sales.

When viewed as an investment rather than a cosmetic upgrade, exterior painting becomes a strategic decision that supports both short-term enjoyment and long-term financial value.

Final Thoughts

A successful project requires more than choosing a color and applying a few coats. It demands a clear understanding of materials, meticulous preparation, thoughtful product selection, and skilled application. When all these elements come together, the result is a durable, attractive finish that protects and enhances a property for years.

By respecting the process and recognizing its importance, property owners can ensure that exterior painting delivers on its promise of beauty, protection, and lasting performance without unnecessary surprises or premature wear.