Introduction

In today’s world of product development, engineers face constraints from traditional manufacturing, which involve longer cycles and more expense. CNC Machining integrates digital design with automated and high-precision production to address this issue. It allows enhanced flexibility, reduced human error, and entails strict quality control that effectively translates creative concepts into tangible products efficiently.

What is Modern CNC Machining and How Does It Serve as a Cornerstone of Precision Manufacturing?

A report by the Manufacturing Institute on the role of automation in enhancing manufacturing competitiveness points out that contemporary CNC Machining comprises a Digital Subtractive Manufacturing Process that essentially sustains itself at the very center of Digital Fabrication. It works by translating a digital three-dimensional blueprint (CAD file) into a corresponding set of machine-operable instructions (G-code), which in return independently controls the action of the cutting tools to remove material from a solid material object with stunning precision.

The basic Machining Process of the computerized system calledCNC machining milling essentially involves an uninterruptible continuum from design to final physical object, hence its cycles of programming, setting up the machine, and execution of the designed object. It’s the unmatched automation, precision, repeatability, and capacity to work with unimaginably complex shapes of the entire machine itself that makes the entire system unique compared to the conventional physical machining process in the sense that no manual tool can be more precise to the milling meter or better still to the micron.

Why Can CNC Milling Applications Unleash Unprecedented Design Freedom?

Unleashing Geometric Freedom and Precision

The core power of CNC milling applications lies in the unique capability for fabrication that it possesses- complicated geometries, organic surfaces, and ultra-precise features not achievable or prohibitively expensive by other means. This technical capability directly translates into empowering the engineers to do more ambitious Creative Solutions with the removal of traditional manufacturability constraints from the initial design phase.

A Varied Toolkit of Milling Operations

This freedom of design is made possible by the versatility of Types of CNC Milling Operations, each suited for a particular type of operation.

- Foundational Operations for Structure

These include milling the face for the purpose of creating flat reference surfaces and the pocket milling where cavities and recesses are excavated.

- Advanced Operations for Complexity

This includes contour profiling to complex 2D outlines and the transformative capability of 5-axis simultaneous machining, which builds complex 3D forms in a single setup.

Enabling a Design-Driven Paradigm

These kinds of operations, in mass, remove the limitations posed to designers when dealing with simplistic geometries. They are able to express themselves in more complex components, lightweights, and sculpted surfaces. There is, in fact, a paradigm shift from “manufacturing-limited design” to “design-driven manufacturing,” where the capacity to precisely machine an array of features is the key innovation trigger.

In Quality Control, What Advantages Does Precision CNC Milling Offer Over Traditional Methods?

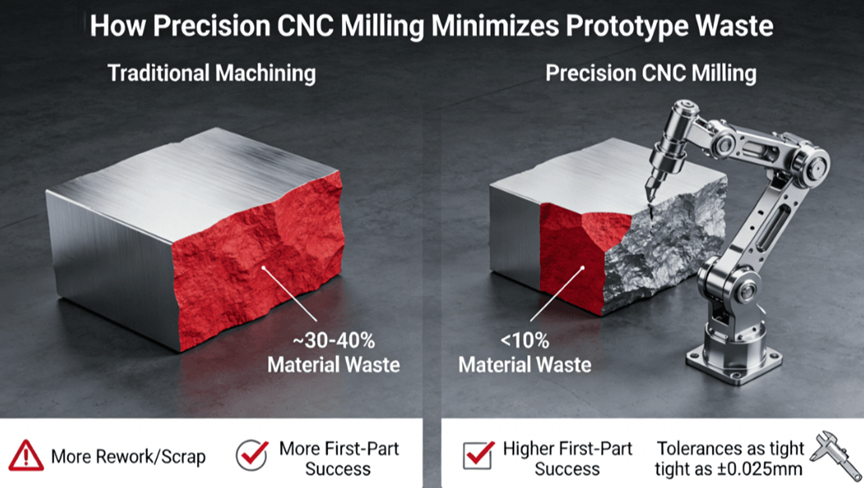

A Proactive, Integrated Quality Philosophy

Precision CNC Milling Quality Control as a BasicIntegrated Process, Not a Final Touch. It brings about a change in quality assurance from a “reactive, downstream process, after production, to a proactive process integral to all production steps.” It starts in a digital realm, preventing programming errors, collisions, and optimizing tool paths based upon simulations prior to cutting a metal.

Precision CNC Milling uses computer-assisted design (CAM) for programming, optimizing, analyzing, manipulating, synthesizing, simulating, rehabilitating, integrating, modifying, merging, analyzing, documenting, creating, producing, developing, refining, enhancing,

In-Process Assurance Through Advanced Technology

Because of this, the capability created during programming is protected in the course of execution using a combination of adequate hardware as well as intelligent monitoring techniques.

- Foundation for Consistency

A combination of high-performance tooling, stiff machine platforms, and high-precision motion control delivers a high degree of cutting consistency and accuracy.

- Real-Time Monitoring & Correction

On-machine probing allows the measurement of key dimensions in a machine. This key dimension measurement allows automatic compensation for variation like tool wear or temperature drift, ensuring the product meets the dimensions correctly regardless of the variation.

The Tangible Outcome: Reduced Defects and Guaranteed Conformance

This is a systematic, in-process approach that starkly contrasts with traditional forms of manual inspection, which are always based on samples. The advantages of precision CNC milling include embedding checks throughout, thus drastically reducing scrap rates while guaranteeing that each finished part reliably matches its digital model perfectly. This high level of process capability and consistent outcomes is very often formally structured and validated through certified quality management systems.

How Does Integrating CNC Machining Services Significantly Enhance Overall Workflow Productivity?

Implementation of professional CNC Machining Services into a product development cycle turns an exterior contract manufacturer into a strong Productivity Tools. This approach enables a company to expand its manufacturing capacity in an efficient manner without involving huge capital expenditures in machine procurement, personnel, or investments in their training.Now, for start-ups and R&D teams, it leads to the utilization of Precision Manufacturing services on a high level without much capital investment, thereby compressing the learning curve to achieve a rapid prototype to working model.

The benefits for an established firm involve the ability to outsource to address technical expertise or use it to supplement their capacity to handle production peaks. The outsourcing approach allows an organization to redirect their capacity to innovate and focus on their core strengths like design innovation, R&D, and market entry. The approach supports building an agile, responsive, and efficient manufacturing enterprise that has a reaction time to produce prototypes within a lead timeline of 1-3 days. The approach essentially converts a capital-cost item into a variable cost that has a positive influence on productivity.

What Key Capabilities Should Be Prioritized When Selecting a Precision Machining Partner?

The Role of the right partner in precision machining in the success of the project.Contrary to the traditional view of comparing various machine brands when looking for a company to perform precision machining, the criteria of comparison or selection should be extended to a wide field of relevant expertise surrounding precision manufacturing and quality control.

Factors that are critical in this area include expertise, handling the precision of the machine tool, the level of complexity in the CAM software, and in-depth process knowledge specific to materials. An article by the UK’s National Physical Laboratory (NPL) on the role of metrology in ensuring manufacturing quality emphasizes factoring in the importance of the quality control process, the commitment to quality on the part of any partner is reflected in the appropriate level of certifications, as well as their utilization of advanced metrology instruments like Coordinate Measuring Machines in final checks.

Apart from that, flexibility in manufacturing, or the ability to efficiently handle orders involving individual units as well as high volume production, is an absolute necessity in order to properly support any particular product for diverse stages in its life cycle. Technical knowledge of various materials, effective communication, and proper project management are some of the critical, though less-tangible, requirements for an effortless and fruitful collaboration. Choosing the right collaborator, thereby having exceptional competence in these areas, ensures that the highest standards in precision manufacturing and quality control are imprinted in their work.

Conclusion

In all, modern precision CNC machining is much more than a specialized, standalone cutting technology; it is a holistic productivity solution integrating digital design with automated execution and tight process control. Thanks to the unrivaled precision, flexibility, and repeatability, it effectively bridges the chasm between innovative concepts and commercial products and provides key support to tackle complex engineering challenges and enhance manufacturing competitiveness.

When looking to bring ideas to reality with efficiency and precision, an understanding of the vast benefits of precision CNC milling services can be the backbone of the success of your project.

Author Biography

The author is a precision manufacturing expert at JS Precision. With over a decade of experience, he specializes in helping medical and aerospace innovators overcome complex design for manufacturability challenges.TheISO 9001:2015 certified processes ensure part quality and accelerate time-to-market.

FAQ

Q1: What kinds of products can be CNC machined?

A: CNC machining is preferred for manufacturing prototypes, molds, and finished goods having complicated shapes and tight tolerances. This type of machining operation is widely used for aerospace, the medical sector, the automotive sector, as well as consumer electronics.

Q2: Is CNC machining or 3D printing a better option?

A: Overall, typically, the benefit of the CNC process may include the characteristic of the material, surface finish, accuracy, and the materials employed in the CNC process, especially metals, which may be of benefit in the production of functional parts that need high mechanical strength.

Q3: What are the main cost drivers that influence the CNC machining part?

A: These are: complexity of part design, material, number of pieces, time in the machining process, and the requirements of the secondary processing steps related to surface finish. Design optimization is effective in controlling the costs.

Q4: What is the accuracy that can be achieved on the CNC?

A: The achievable level of tolerance on modern precision CNC machines depends from machine to machine and varies between ±0.025 mm to ±0.0025 mm depending on machine type, tools, and materials used.

Q5: What is the average lead-time from design submittal to the receipt of CNC machined components? A: Influencing factors include the complexity of projects and the capacity of suppliers. Simple items take 1-3 business days in rapid prototyping, while complex ones take several weeks for mass production services. Specific timelines are provided by the dedicated service providers themselves.